Introduction to Filling Machines

Investing in filling machines can seem like a daunting decision for businesses, big or small. With so many options on the market, how do you know where to start? The economics of investing in filling machines goes beyond just initial costs; it’s about understanding long-term returns on that investment. From reducing labor costs to increasing efficiency, these machines can be game-changers for your operations. But before you make that leap, let’s dive into what makes a filling machine worth its weight in gold and explore how this choice could reshape your business landscape for years to come. Buckle up as we break down the essentials of cost versus long-term ROI!

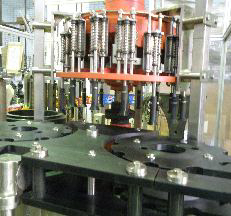

Types of Filling Machines

Filling machines come in various types, each designed to meet specific production needs. The most common are volumetric fillers. These measure a precise volume of liquid to be dispensed into containers.

Piston fillers use a piston mechanism for accurate filling. They excel with thicker liquids and pastes, making them ideal for food products or cosmetics.

Gravity fillers rely on the force of gravity and are perfect for thin liquids like water or juice. Their simplicity makes them easy to operate.

Pump fillers utilize mechanical pumps, allowing for consistent flow rates. They’re versatile and can handle different viscosities effectively.

Specialized machines such as vacuum fillers cater to niche markets by preventing foaming during the filling process, especially important in the beverage industry.

Selecting the right type depends on your product specifications and production scale. Each offers unique advantages that can streamline operations significantly.

Initial Cost vs. Long-Term ROI

When assessing filling machines, initial cost often takes center stage. Many businesses focus solely on the price tag, but this narrow view can be misleading.

A high upfront investment may deter some, yet it’s essential to consider what those machines bring over time. Advanced technology usually means enhanced efficiency and reduced labor costs. This balance can tip the scale favorably toward long-term ROI.

Moreover, cheaper alternatives might save money initially but could result in higher maintenance expenses or frequent breakdowns later on. These hidden costs quickly stack up.

Investing wisely involves looking beyond today’s budget constraints and weighing future benefits against current expenditures. Understanding how these factors intertwine provides clarity in making informed decisions for your business’s growth trajectory.

Factors to Consider when Investing in a Filling Machine

When investing in a filling machine, consider the type of products you’ll be packaging. Different machines cater to various liquids, powders, or granules. Make sure to choose one that aligns with your production needs.

Next, evaluate the machine’s speed and efficiency. A higher output can significantly impact your overall productivity. This is especially crucial for businesses looking to scale.

Don’t overlook maintenance costs. Some machines require more upkeep than others, which can affect long-term expenses. Research warranties and service agreements before making a commitment.

Also think about space constraints in your facility. Ensure you have sufficient room for installation and operation without hindering workflow.

Assess technology compatibility. The right machine should seamlessly integrate with existing systems like inventory management or quality control processes for optimal performance.

Case Studies: Companies that have Invested in Filling Machines and their Results

A notable example is a leading beverage company that incorporated automated filling machines into its production line. The switch led to an impressive 30% increase in throughput within six months. This efficiency boost significantly reduced labor costs and minimized product waste.

Another case involves a cosmetics manufacturer that transitioned from manual filling processes to semi-automated systems. Their investment not only improved consistency but also cut down on production time by 40%. As a result, they managed to meet rising consumer demand without sacrificing quality.

In the food industry, a sauce producer upgraded their filling technology and reported an astonishing reduction in compliance-related fines due to enhanced precision. With fewer errors, they enjoyed better customer satisfaction rates as well.

These examples illustrate how strategic investments in filling machines can lead to exceptional operational outcomes across various sectors.

Tips for Maximizing ROI on Filling Machines

To maximize ROI on filling machines, start with regular maintenance. Scheduled upkeep prevents unexpected breakdowns and extends machine life.

Training your staff is just as important. Well-trained operators work efficiently and reduce waste caused by errors.

Consider integrating automation. Automated systems can boost production rates while minimizing labor costs.

Analyze production data consistently. Understanding trends helps you identify inefficiencies in the process, allowing for timely adjustments.

Invest in high-quality materials for packaging to ensure durability and minimize returns due to damaged products.

Keep an eye on market demand fluctuations. Being adaptable lets you adjust production schedules effectively, ensuring that you’re always meeting customer needs without overextending resources.

Conclusion

Investing in filling machines is a significant decision for any business, particularly those in the manufacturing and packaging sectors. Understanding the economics behind such an investment can make a substantial difference in operational efficiency and profitability.

Choosing the right type of filling machine to match your specific needs is crucial. Whether you require volumetric, gravimetric, or piston fillers, each comes with its own set of advantages that align with different product types and production volumes.

While initial costs may seem daunting, evaluating long-term ROI reveals more about their true value. Analyzing factors such as labor savings, increased productivity, reduced waste, and enhanced accuracy demonstrates how these machines pay off over time.

Several key considerations should guide your purchasing decision: production capacity requirements, maintenance costs, scalability options for future growth—these all play critical roles in ensuring that you select a machine suited to both current demands and future aspirations.

Real-world case studies illustrate this point vividly. Companies across various industries have reported remarkable returns after investing in advanced filling machinery. Their success stories serve as testimonials to the transformative potential of making informed equipment choices.

To maximize ROI on your filling machine investment involves strategic planning and ongoing evaluation. Regularly assessing performance metrics ensures that you’re getting the best out of your equipment while adapting processes as necessary based on market changes.

A well-thought-out approach to investing in filling machines blends cost considerations with long-term benefits seamlessly. Prioritizing quality alongside economic sense leads businesses toward sustainable growth without compromising on efficiency or output quality.