Introduction to AI and Machine Learning

The world of manufacturing is rapidly evolving, and at the forefront of this transformation are artificial intelligence (AI) and machine learning. These cutting-edge technologies are not just buzzwords; they’re reshaping how industries operate, especially in filling machinery. Imagine a future where machines can learn from their environments, optimize processes in real-time, and significantly reduce waste—all while increasing production efficiency. This isn’t science fiction; it’s happening right now.

As companies race to adopt these advancements, understanding their implications becomes essential for staying competitive. In this blog post, we’ll delve into how AI and machine learning will shape the landscape of filling machinery. Whether you’re an industry veteran or just starting out, it’s time to explore what these innovations mean for your operations. Buckle up as we prepare for a fascinating journey into the future!

The Current State of Filling Machinery

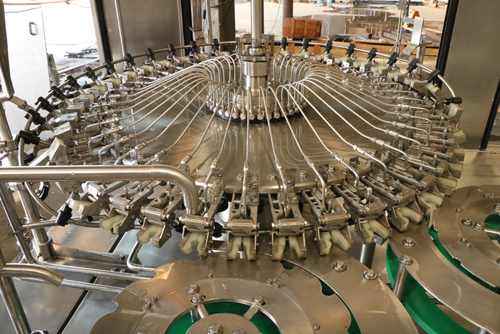

Filling machinery has come a long way in recent years. It serves various industries, from food and beverage to pharmaceuticals. Today’s machines are more efficient and precise than ever before.

Automation plays a significant role in this evolution. Manufacturers strive for increased productivity while minimizing waste. Advanced filling systems can handle different container sizes and shapes with ease.

Yet, the industry faces challenges too. Variability in product viscosity and consistency can complicate the filling process. Companies must adapt their equipment to meet diverse demands without compromising quality.

Moreover, regulatory compliance remains essential. Each sector has specific standards that machinery must meet for safety and efficacy.

As technology evolves, so do consumer expectations for speed and accuracy. The pressure is on companies to innovate continuously within this competitive landscape of filling machinery.

Advancements in AI and Machine Learning for Filling Machinery

Advancements in AI and machine learning are transforming filling machinery at an impressive pace. These technologies enable machines to learn from data, adapt to different products, and optimize processes without constant human intervention.

Smart sensors now monitor filling levels with precision. They reduce waste by ensuring that each container receives the exact amount needed. This not only enhances efficiency but also improves product quality.

Predictive maintenance is another game-changer. Machine learning algorithms analyze operational data to foresee potential failures before they happen. This proactive approach minimizes downtime and saves on costly repairs.

Additionally, AI-driven analytics provide insights into production patterns and consumer demands. Companies can adjust their operations based on real-time feedback, leading to better decision-making.

The integration of these advancements offers a glimpse into a more efficient future for filling machinery that responds intelligently to changing market needs.

Benefits of Incorporating AI and Machine Learning in Filling Machinery

Incorporating AI and machine learning into filling machinery brings remarkable advantages. Enhanced precision is one of the primary benefits. These technologies can analyze data in real-time, ensuring that every fill meets stringent quality standards.

Efficiency gains are another significant aspect. Automated systems reduce downtime and optimize production schedules. This means faster turnaround times and increased output without compromising on quality.

Predictive maintenance also plays a vital role. By continuously monitoring equipment performance, businesses can foresee potential issues before they lead to costly breakdowns.

Furthermore, cost savings emerge from reducing waste through accurate measurements. Companies using smart algorithms can minimize product loss during the filling process.

Adaptability stands out as a key trait of these advanced systems. They easily adjust to different products or changes in demand, making operations more flexible than ever before.

Potential Challenges and Concerns

While the integration of AI and machine learning in filling machinery offers numerous benefits, several challenges must be addressed. One primary concern is the initial investment. Upgrading existing systems to incorporate advanced technologies can be costly for many businesses.

Another challenge lies in data security. As machines become smarter and more interconnected, they may also become vulnerable to cyber threats. Protecting sensitive information will require robust cybersecurity measures.

Furthermore, there’s a skills gap in the workforce. Many employees may lack the necessary training to operate sophisticated AI-driven systems efficiently. This skill shortage could hinder smooth implementation and operation.

Reliance on technology raises questions about human oversight. Ensuring that skilled personnel remain involved in decision-making processes is vital for maintaining quality control and minimizing risks associated with automation.

Case Studies of Successful Implementation

A notable example of successful AI implementation in filling machinery comes from a beverage company that integrated machine learning algorithms into its operations. By analyzing historical data, the system was able to predict when maintenance was needed, reducing downtime significantly.

Another case involves a cosmetics manufacturer that employed AI for real-time quality control. The technology detected inconsistencies during the filling process, allowing operators to adjust parameters on-the-fly. This resulted in fewer product defects and higher customer satisfaction rates.

In both cases, automation combined with advanced analytics led to enhanced efficiency. These companies not only improved their operational output but also gained valuable insights into market demands through predictive analysis.

These success stories showcase how embracing AI can transform traditional processes into smart manufacturing systems, paving the way for future innovations in filling machinery.

Preparing for the Future: What Companies Need to Do Now

To prepare for the future, companies must take proactive steps now. Embracing AI and machine learning is not just an option; it’s becoming essential.

First, organizations should invest in training their workforce. Upskilling employees ensures they understand and can work alongside advanced technologies effectively.

Second, adopting a pilot program to test AI solutions can provide invaluable insights. Starting small allows companies to gauge effectiveness without overwhelming resources.

Collaboration with technology providers is crucial as well. Partnering with experts can accelerate implementation and tailor solutions to specific needs.

Fostering a culture of innovation encourages adaptability. When teams are open to experimentation, they’re more likely to embrace new tools that enhance productivity.

These strategies will position businesses favorably as the landscape evolves rapidly in response to technological advancements.

Conclusion

The integration of AI and machine learning into filling machinery represents a transformative step for the industry. As technology continues to advance, companies must adapt to stay competitive. Embracing these innovations can lead to increased efficiency, improved accuracy, and reduced operational costs.

However, organizations should also remain mindful of the potential challenges that accompany these advancements. Data security concerns and the need for skilled personnel are key considerations. By addressing these issues proactively, businesses can pave the way for successful implementation.

Learning from case studies demonstrates that many have already begun their journey successfully. These examples provide valuable insights into best practices and strategies for harnessing AI’s power effectively.

As we move forward, it is evident that preparation is crucial. Companies need to invest in training their workforce, upgrading existing machinery where necessary, and exploring partnerships with tech providers specializing in AI solutions.

Staying ahead means not only recognizing future trends but actively engaging with them now. The landscape of filling machinery will undoubtedly evolve as AI becomes increasingly integrated into operations—those who prepare today will be ready for tomorrow’s opportunities.